Parason Magstruct™ - MT

Sturdy, fabricated stainless steel magnetic trap with large permanent magnets for improved metallic contaminant removal efficiency.

Loading...

Sturdy, fabricated stainless steel magnetic trap with large permanent magnets for improved metallic contaminant removal efficiency.

Sturdy, fabricated stainless steel construction with large permanent magnets for maximum contact area, delivering improved removal efficiency of metallic contaminants from the stock line.

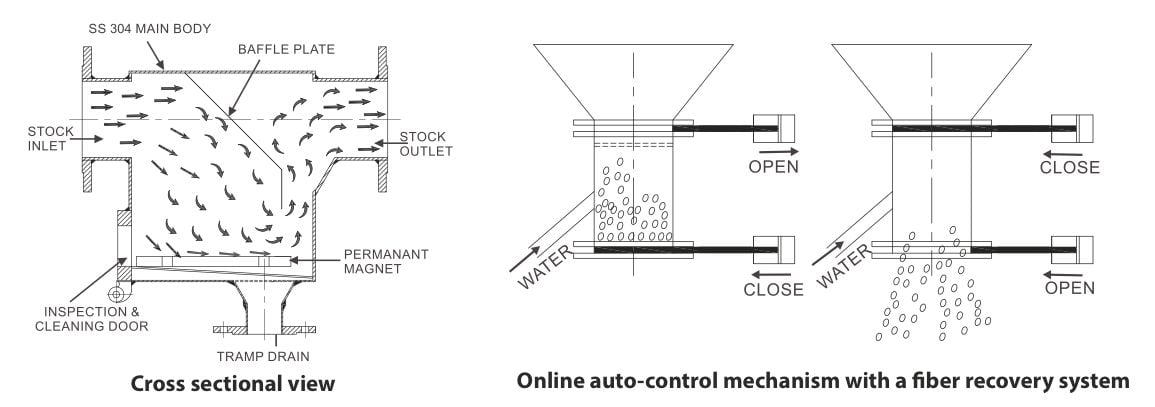

The Magstruct™ - MT features a well-shaped body that assists other non-magnetic tramps for gravity separation, with periodic cleaning made easy through the inspection & cleaning door and tramp drain. Auto arrangements ensure excellent results in continuous operation.

More contact area ensures superior removal efficiency of metallic contaminants from the stock line.

Permanent magnet technology requires no electricity, no moving parts, and no flush water for operation.

Stainless steel main body ensures long-lasting durability and corrosion resistance in demanding mill environments.

Online auto-control mechanism with fiber recovery system, plus easy periodic cleaning through inspection door and tramp drain.

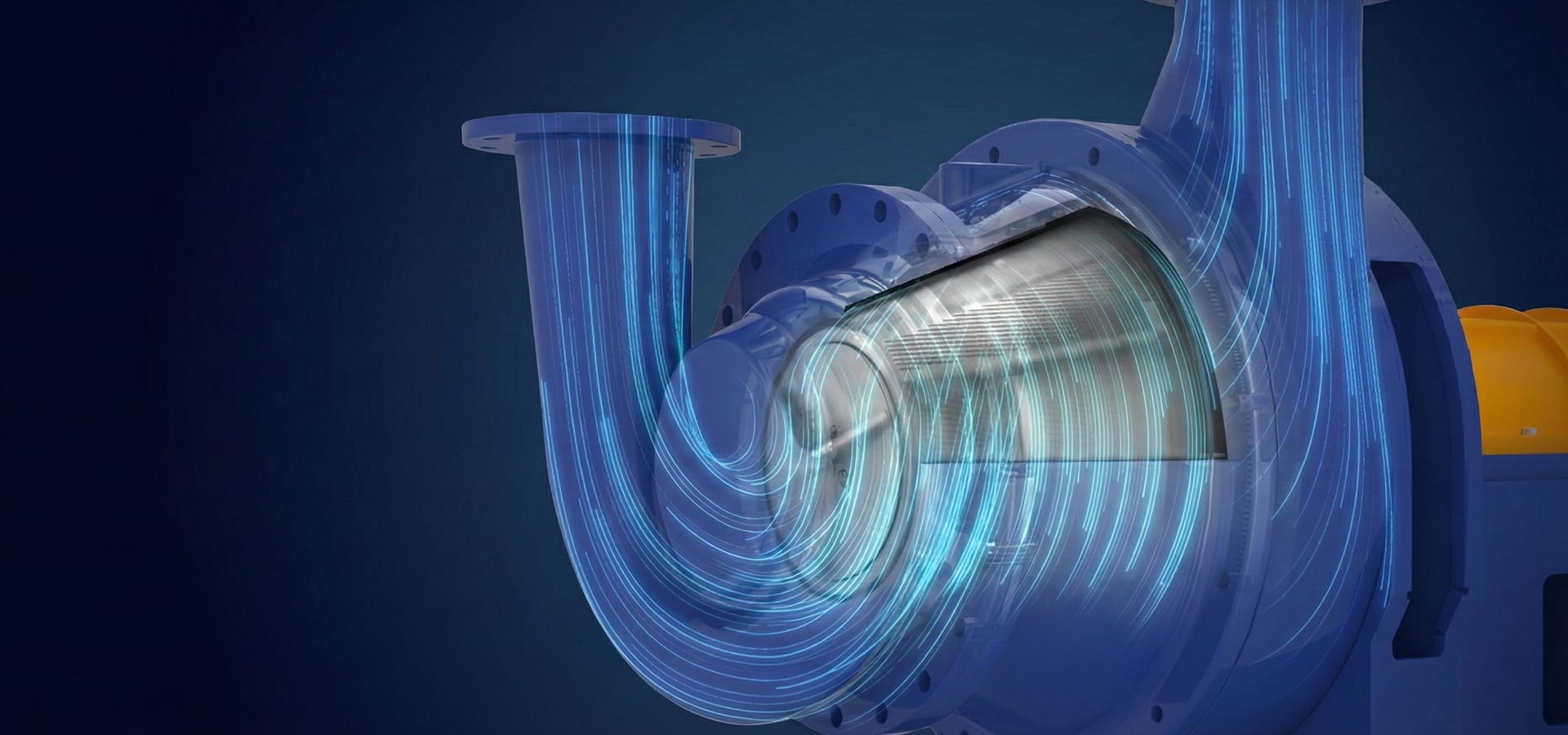

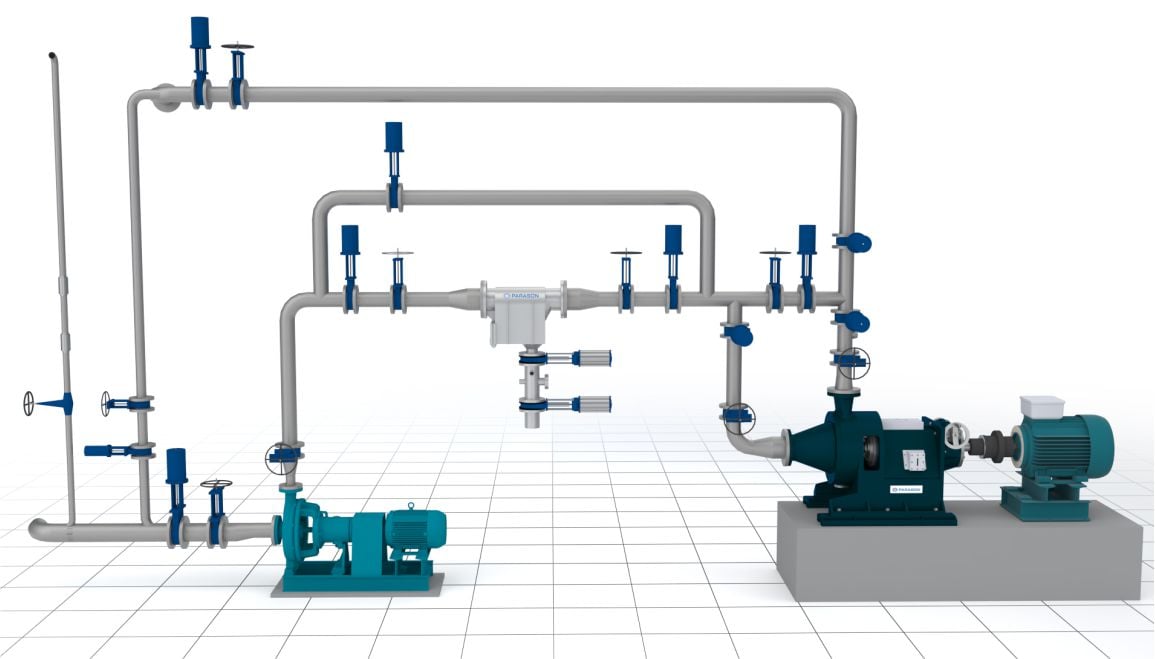

The Magstruct™ - MT is designed for seamless inline installation between the stock pump and refiner, providing a critical protection barrier that removes metallic contaminants before they reach expensive downstream equipment.

Integration

Plug & Play

Direct flange-to-flange connection

Protection

Before Refiner

Safeguards refiner plates & fillings

Recovery

Auto Fiber Recovery

Online cleaning with zero fiber loss

Engineered for reliable contaminant removal with zero operational costs

Cross Sectional View

Online Auto-Control Mechanism with Fiber Recovery System

Key specifications at a glance

Available in 4 models: MT-06, MT-08, MT-10, MT-12. Custom configurations available upon request.

Install the Magstruct™ - MT magnetic trap to safeguard your refiners and downstream equipment from metallic contaminants. Contact us for the right model for your stock line.