If you're planning to set up a paper mill plant, you probably have a lot of questions. After all, establishing a complete pulp and paper mill as well as starting a paper manufacturing business is no easy task.

However, you've come to the right page to help you get started. Here's a detailed guide that will answer all your questions about starting a paper mill, from pre-planning to the production process, and more.

The 3 basic building blocks to set up a paper mill

As with any other business, paper mills also have three building blocks that are essential for them to function efficiently. Here's what they are.

Brand

Your brand is more than just the name of your paper manufacturing business. It is what people will use to identify your business with, and will be synonymous with the quality of your products.

Labor

Skilled labor is of paramount importance to the development of any paper mill. The quality of your products, cost of production, production techniques and more will eventually depend on the availability of skilled labor.

Capital

Capital is an important part of setting up a paper mill factory. You need to have enough capital to be able to afford a good location, raw material, good infrastructure, adequate marketing, logistics, as well as the best pulp and paper machines.

Pre-Project Activities

Let us now take a quick look at some essential pre-project activities you need to consider as a part of setting up your paper mill.

1. Select the Paper Grade to Produce

The market has numerous varieties and grades of paper, each of which requires different machinery and has a different manufacturing process.

Choosing your end product is crucial to the success of your paper mill, and you have to consider various aspects to make an educated decision. Here are some key aspects that you have to go through while selecting the grade of paper you want to produce.

Market Demand

Conduct in-depth research to learn about the demand for various paper grades in various markets, trades, and consumer groups. You could also connect with paper distributors to learn about market trends, such as which grade of paper is most in demand.

Availability of Raw Materials

Consider the availability and price of raw resources such as pulp, fibers, and chemicals needed for the paper you want to manufacture.

Manufacturing Expertise

Running a successful paper mill plant also requires a competent team of engineers and consultants. Be sure to employ a team with domain experience, determine the level of experience they have, and ensure they receive the training they need to be proficient.

Competition

Check out who your direct competition is, what their market share is and how their products are priced.

Profitability

Analyze how profitable your paper mill venture could be, taking into consideration factors such as production costs and market shares.

2. Choose the Right Location

Scoping out the ideal location for your new paper mill plant could be more complicated than you’d expect. Here are some factors to keep in mind while choosing the right location.

Availability of Raw Materials

When considering a suitable site for establishing a paper manufacturing plant, it is imperative to prioritize proximity to a reliable and cost-effective source of raw materials, including but not limited to wood, pulp and recycled paper.

This strategy allows for a considerable reduction in transportation expenses and guarantees a dependable supply chain.

Transportation and Logistics

In the realm of paper industry operations, it is imperative to have easy access to transportation infrastructure, such as roadways, railways, and ports.

This evaluation is crucial in ensuring the smooth and efficient transportation of raw materials to your paper mill plant as well as the supply of finished paper products from your plant to the market.

Labor Force Availability

The evaluation of labor force availability is a crucial aspect when selecting a location for paper industry operations. It is essential to assess the availability of a skilled and qualified labor force in the chosen location.

Take into account factors such as the demographics of the surrounding community, as well as the presence of academic institutions and vocational training centers that can furnish a labor pool with pertinent knowledge and skills.

Market Accessibility

When evaluating market accessibility, it is imperative to take into account the proximity to the intended markets and clientele. Proximity to key customers is a strategic advantage that can result in reduced transportation expenses and improved delivery timeframes, ultimately enhancing customer service levels.

3. Choose a Partner for Machinery, Equipment and Engineering

The installation and commissioning of a paper mill plant is a technically complex process, and requires various engineering operations, such as raw material analysis, creating 2D and 3D layouts of the paper mill and mass balancing.

Selecting a machinery supplier partner with the required expertise and a proven track record is very important to ensure that commissioning your new paper plant is hassle-free and seamless.

Here are some factors for you to consider while choosing a vendor for your machinery and engineering needs.

Availability of All Necessary Pulping and Paper Machinery

It is essential to make sure that your selected partner has all the required machinery for your paper mill such as the equipment required for diverse paper manufacturing processes including pulping, screening, bleaching, drying, and finishing.

Having a single supplier for all the required machinery streamlines the procurement process and ensures compatibility and efficient integration of equipment.

Reliability of Engineering Support

During the installation and commissioning phase of your new paper mill, reliable engineering support is crucial. The machinery manufacturer and supplier should have a dedicated team of engineers who can provide technical assistance, troubleshoot issues, and offer guidance throughout the project.

Their expertise and prompt support can significantly minimize downtime and optimize the mill’s performance.

Great After-Sales Service

Continuous upgradation and maintenance play a vital role in the long-term success of a paper mill. Choose a machinery manufacturer and supplier known for their commitment to after-sales support.

This includes timely maintenance, spare parts availability, and assistance with any operational challenges that may arise. A partner with a good record of after-sales service ensures uninterrupted production and maximizes the lifespan of your machinery.

Technical Expertise

The installation and commissioning of a paper mill plant involves intricate engineering operations. It is essential to collaborate with a machinery manufacturer and supplier who has a deep understanding of the pulp and paper industry.

Look for a partner with extensive technical expertise in designing, manufacturing and delivering machinery specifically tailored to the requirements of a paper mill.

Proven Track Record

Experience matters when it comes to setting up a paper mill plant. Be sure to partner with a machinery manufacturer and supplier with a proven track record of successfully delivering projects and meet customer expectations.

Research the company’s history, explore their portfolio, and inquire about their past projects to evaluate their performance and reliability. Additionally, consider requesting records or testimonials from commissioned paper mills that have worked with the selected partner.

Engineering Processes to Set up a Paper Mill Plant

Let’s now dive into the engineering processes you will need to oversee while setting up your paper mill plant.

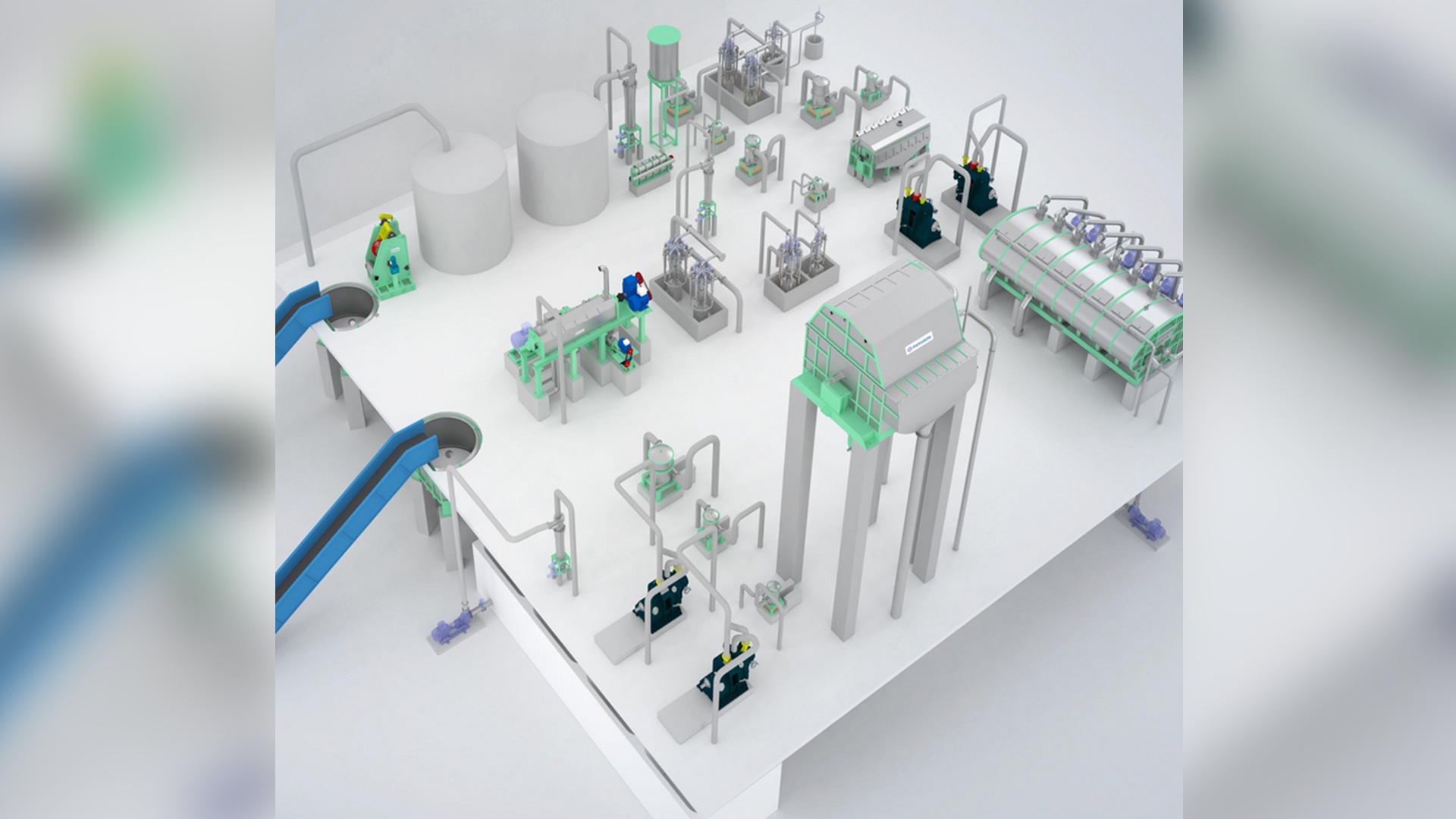

Stock Preparation and Equipment Sizing

Based on factors such as the raw materials to be used for production and the targeted production capacity (measured in TPD or tons per Day), your machinery manufacturer and supplier partner will provide you with a primary techno-commercial offer.

Ideally, along with commercial aspects, this primary offer ought to also include the sizes and capacities of all the stock preparation machinery you will need. These machines include the pulper, refineries, pulp screening and screening machinery, approach flow systems, as well as paper machinery sections like pressing, drying, sizing, and calendaring sections.

Conceptual plant layout

The layout of a paper mill plant or process line is a crucial step that forms the foundation for subsequent engineering activities. Several factors need to be considered to develop an optimal layout, including the amount of space available, existing equipment, efficient material flow, maintenance access, minimal piping and ducting requirements, and optimized building size.

Load plans are essential documents for civil engineering, providing information that help in static and dynamic calculations of the building and machine track. This includes equipment loads, pipe system loads, paper machine loads, earthquake factors, and main openings.

Mass Balance of Plant

The overall efficiency and cost-effectiveness of a paper mill depends on the interoperability of its systems. Achieving an optimal solution requires a comprehensive understanding of the mill’s energy, raw material, water and effluent balances.

By analyzing these balances and defining the interfaces between various sections, such as stock preparation, the wet-end process, paper machine, auxiliaries, effluent plant and power plant, the best configuration for the Balance of Plant (BoP) can be determined. This ensures different sections of the mill are efficiently integrated and are functioning optimally.

Process and Instrumentation Diagram

The close relationship between process engineering and automation engineering is evident through their shared use of equipment and resources. By utilizing a single database with distinct templates for automation and engineering, both departments can benefit from streamlined processes, improved data quality, and reduced errors.

This approach allows for efficient data input, leading to a shorter overall engineering period and enhanced project outcomes.

3D Plant Layout and Detailed Engineering

To streamline the procurement, engineering, and installation processes, a cutting-edge 3D plant model is utilized. This model encompasses the entire machinery, piping, ducting, steelwork and main cable trays.

By integrating the design models of the machinery within the plant model through an interface, a comprehensive 3D representation of the paper mill plant can be achieved. This approach allows all engineering disciplines to collaborate from the project’s inception, facilitating efficient document generation for all third parties involved, such as civil contractors.

Piping

In a paper mill, the machinery require a network of pipe systems to connect them. Compliance with local regulations, such as the Pressure Equipment Directive, and mill standards is essential. Special pipes, like steam pipes, require stress calculations to meet regulatory requirements.

The output of piping engineering includes isometric drawings, bill of materials, and drawings for piping supports. The number of pipelines can vary, ranging from approximately 200 for a tissue line to up to 8000 for a newsprint mill with deinked pulp (DIP).

Final Installation and Commissioning

With all the planning aspects out of the way, this is the part of the process that deals with installing all the equipment your paper mill plant will need and commissioning it.

Integration of Stock Preparation System

The stock preparation system plays a vital role in transforming raw materials into pulp, which is the foundation for paper production.

During installation, the stock preparation system’s equipment, such as pulpers, cleaners, screens, and refiners, must be properly integrated and aligned. This process ensures the efficient flow of materials and optimal performance of the system.

Approach Flow System Optimization

The approach flow system controls the consistency and cleanliness of the pulp as it enters the paper machine. It includes processes such as dilution, screening and cleaning.

During installation and commissioning, the approach flow system’s components, including pumps, screens, and piping, must be meticulously installed and calibrated. Proper alignment and optimization of the system ensure consistent pulp quality and minimize operational issues.

Paper Machinery Installation

The paper machinery encompasses a range of equipment, including the forming section, press section, dryer section, and calendar. Each component must be carefully installed, aligned, and connected to ensure smooth paper production.

During this phase, proper adjustment of tension, alignment of rolls, and calibration of control systems are critical to achieving the desired paper properties and production efficiency.

Market Your New Paper Mill

Now that your new paper mill plant is set up, it’s time to start bringing in customers, and winning them over with the quality of your paper products.

In order to spread the word about your new paper mill, and to bring in these customers, it is essential that you allocate a budget towards advertising and marketing.

While old school advertising, such as print média, does have a vast reach, it is only when you use it in tandem with online marketing that you will truly reach your desired audience. And once that first customer has been acquired, it is only a matter of time before your reputation as a reliable paper manufacturer is established.

Partner With Parason Machinery for Your New Paper Plant Mill

If you’re looking at setting up a new paper plant mill, or expanding your current paper production set up, look no further than Parason Machinery.

With over four decades of domain expertise, Parason Machinery offers a host of services that you can benefit from. Our turnkey services will take care of every aspect of setting up your new paper mill plant.

We are also leading manufacturers of all the equipment you need, as well as spare parts for every piece of equipment your plant will need. In fact, our spare parts undergo metallurgical component analysis and are capable of withstanding more than normal wear and tear.

Get in touch with our team now, and allow Parason Machinery to build you a paper mill plant that is on par with international manufacturers.